Provide customized design one-stop service

Technical R&D Capabilities

Gitan (Guangdong) Electrode's core technical team has deep technical R&D and industrialization capabilities, and the core management team has rich experience in production, manufacturing and business management.

- 01

Product technical indicators have reached the international leading level

After 3 years of unremitting efforts, Gitan (Guangdong) Electrode has become a well-known enterprise for core materials in the PEM electrolysis hydrogen production industry. It has independent intellectual property rights for more than 20 core technologies. Through independent research and development and mass production of PEM hydrogen production catalysts and membrane electrodes, the product technical indicators have reached the international leading level. At the same time, it has taken the lead in the research and development of low-precious metal and domestic material substitution.

- 02

Self-developed catalysts can adapt to different needs

The catalysts independently developed by Gitan (Guangdong) Electrode can adapt to PEM hydrogen production membrane electrodes with different needs, with a single batch production capacity of more than 500 grams and high batch consistency. Among them, iridium-based catalysts have the characteristics of high catalytic activity and excellent durability; the platinum nanoparticles of platinum-based catalysts are uniform in size and evenly distributed. Both types of catalysts are easy to disperse and slurry, suitable for coating or ultrasonic spraying processes.

- 03

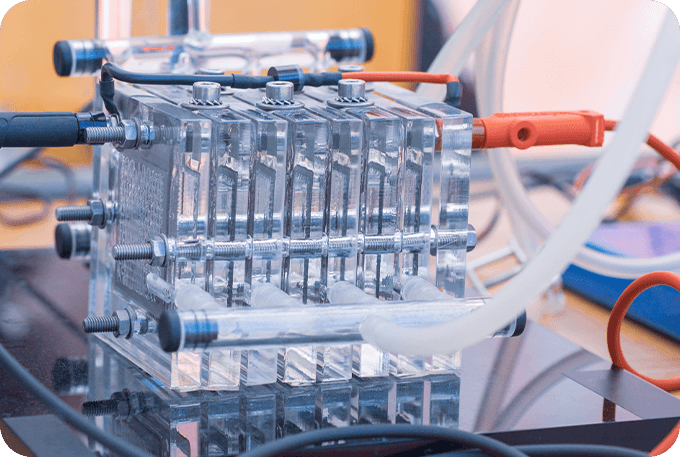

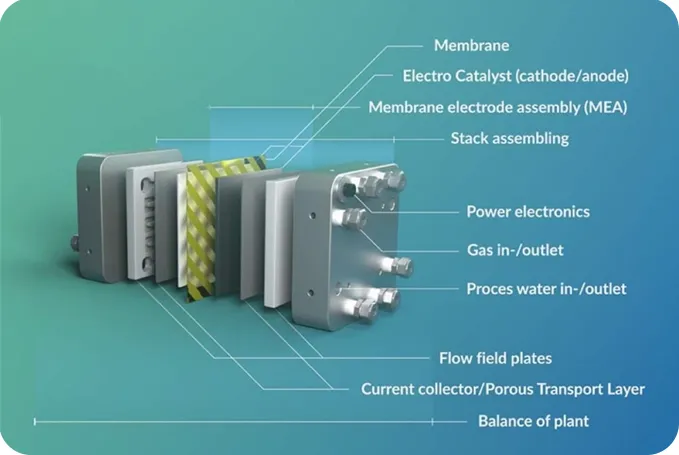

Customized PEM Membrane Electrode

The customized PEM membrane electrode independently developed by Gitan (Guangdong) Electrode can adapt to different PTLs, with a width of up to one meter, and has achieved continuous batch production of large-size membrane electrodes, with uniform product surface state and good consistency in multiple batches.

- 04

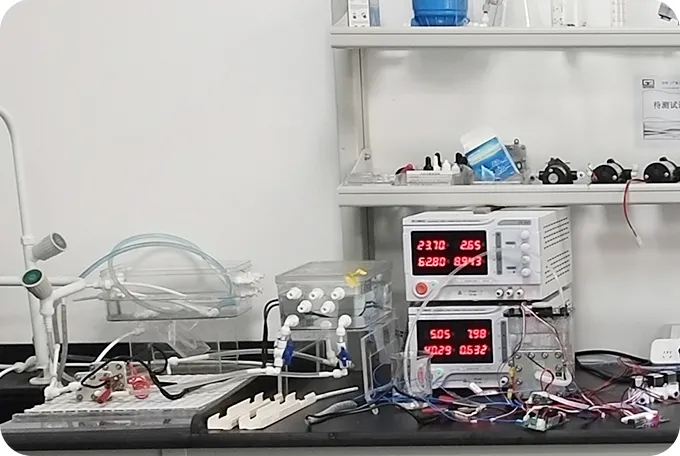

Mature AEM Membrane Electrode CCM Preparation Process

Gitan (Guangdong) Electrode also has a mature AEM membrane electrode CCM preparation process, and masters the independent development and production capabilities of PEM and AEM water electrolysis hydrogen production test benches, which not only supports the large-scale testing needs in the development process of catalysts and membrane electrodes, but also ensures the advanced nature of the company's continuous iteration of products. At the same time, it has been sold as a mature product and has become a new performance growth point for the company.